AMTECH EBM AMBIENT COLLECTORS

Handsfree Fume Extraction for your Welding Shop

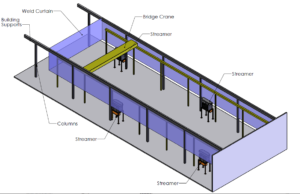

The Clean Air Amtech EBM Ambient Collector offers an easy, effective solution for your welding shop by creating a constant series of air changes in your welding space.

Space: With shop floor space at a premium, the Amtech EBM Ambient Collector series offers an efficient solution for fume extraction. Simply place them in a staggered formation against the walls of your manufacturing space and let them go to work.

Low Maintenance: Traditional hanging units require frequent maintenance that often never gets done. Sure, they are out of the way because they are hanging, but that means someone needs to climb 12 to 14 feet every time the filters need to be changed. Additionally, because of the necessarily compact design, those filters need to be changed almost every month. The Amtech EBM solves this by combining the cleaning system of a traditional dust collector with the space savings of an ambient air cleaner.

Handsfree: One of the main drawbacks of a source capture system (like a portable weld fume extractor) is that it requires the operator to position the fume arm or capture source correctly. The Amtech EBM eliminates this failure point by taking it out of the operator’s hands entirely and functioning automatically.

Reliability: With 30 years of manufacturing industrial air equipment, we have units still in operation that are older than some of our employees!

Made in the USA: From cutting the steel to welding and powder coating, all Amtech EBM Ambient Collectors are manufactured in our facility in Russellville, Kentucky.

Health and Safety

Health and safety issues are being taken very seriously by a growing number of companies as OSHA, International, and industry standards increase. Many large US manufacturers are planning ahead and adopting European exposure limits as a global standard for their entire company and are exceeding OSHA Standards.

To meet these standards companies must implement a highly efficient dust and fume filtration system to filter out the harmful particulate. The exposure limits these companies are targeting range from .02 – 1 mg/m3 depending on company policy, well below the 5 mg/m3 standard set by OSHA.

Request a Quote

Please provide the information below, and one of our experts will be in touch very shortly to help with your air filtration needs.

Applications

Features

– Space Saving

– Optional VFD packages for energy savings

– Heavy-duty cabinet construction made in the USA

– Filter Cleaning

– Handsfree

Benefits

– Eliminates dust and fume from your environment

– Designed to work 24/7 even in high demand applications

– Clean Air Industries can offer turn-key installation

– Removes harmful particles including bacteria

– Main filter life exceeds the industry standard

– Fire Suppression Available

Why the Amtech EBM Series?

– Keep a clean work environment you’re proud to show your customers

– Attract top talent with a safe workspace

– American made with quick service and support when required

– Reliable units that have been pushing the industry standard forward for over 30 years.

Technical Specifications

| Model | Motor | CFM | Volts/Phase/Hz | Amps | Weight | Width | Height1 | Depth | Noise | Dust Tray | Filter Type |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Amtech EBM-8 | 10 HP | 6000 | 230, 460V/3/60Hz | 22.8, 11.4 | 2000 lbs | 81" | 123" | 59" | 78 dBA @ 5' | 27 gal | Fire Retardant 80/20 Cellulose/Polyester 36"x12.75" 99.5% @ 0.5 microns (8x) |

Custom Designs & Modular Configurations

Clean Air Industries can modify units to fit your specific application. Everything from ceiling clearance, to floor space can effect what you need. As we cut and weld everything in-house, we are able to accommodate your needs as required.