Thermal Spraying

What is Thermal Spraying?

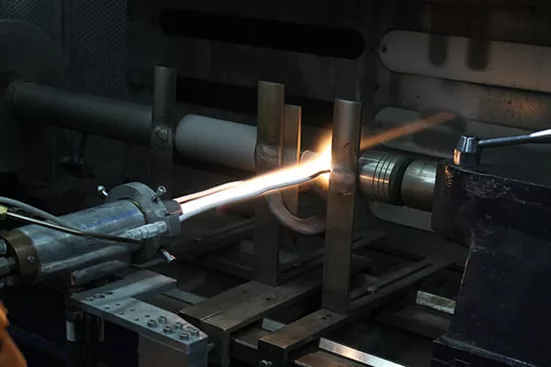

Thermal spraying is a coating process that involves heating and propelling molten or powdered materials onto a surface. The materials used in thermal spraying can include metals, ceramics, polymers, and composites. The coating materials are melted or heated to a high temperature and then sprayed onto the target surface using a specialized thermal spray gun.

Thermal spraying is a coating process that involves heating and propelling molten or powdered materials onto a surface. The materials used in thermal spraying can include metals, ceramics, polymers, and composites. The coating materials are melted or heated to a high temperature and then sprayed onto the target surface using a specialized thermal spray gun.

Thermal spraying is used for various purposes in manufacturing and industrial applications. It is commonly employed for the following reasons:

- Surface Protection: Thermal spraying can provide a protective coating to surfaces, enhancing their resistance to wear, corrosion, and erosion.

- Thermal Barrier Coatings: These coatings are used to insulate surfaces from high temperatures, improving the thermal efficiency and performance of components like turbine blades in gas turbines.

- Functional Coatings: Thermal spraying can apply coatings with specific properties, such as electrical conductivity, thermal conductivity, or low friction, to improve the performance or functionality of parts.

- Restoring Dimensions: Worn or damaged parts can be restored to their original dimensions by applying a coating through thermal spraying, extending their lifespan and avoiding the need for replacement.

Regarding its impact on air quality within a manufacturing facility, thermal spraying can potentially release particulate matter and fumes into the air. The primary concerns related to air quality arise from the process of melting and spraying the coating materials, which can generate airborne particles and emissions.

Impact on Indoor Air Quality

The impacts on air quality depend on several factors, including the specific materials being sprayed, the ventilation system in place, and the control measures implemented. Some of the potential effects include:

- Emissions: Thermal spraying may release gases or fumes, especially when certain coating materials contain volatile compounds. These emissions can potentially contribute to air pollution and may have health and environmental implications.

- Particulate Matter: The process can generate fine particles, which may include metal oxides or other compounds, depending on the coating material. These particles can remain suspended in the air and contribute to air pollution if not properly controlled.

What You Can Do

To mitigate the impact on air quality, manufacturing facilities that employ thermal spraying often implement various control measures. These may include:

- Ventilation Systems: Proper ventilation systems with adequate air exchange rates can help capture and remove airborne particles and fumes from the working area.

- Air Filtration Systems: Installing appropriate filtration systems, such as high-efficiency particulate air (HEPA) filters, can help capture and remove particles from the air.

- Local Exhaust Ventilation (LEV): Locally placed exhaust systems near the spraying process can effectively capture and control emissions at the source, minimizing their dispersion into the surrounding environment.

- Personal Protective Equipment (PPE): Workers involved in thermal spraying should wear appropriate PPE, including respiratory protection, to minimize their exposure to airborne contaminants.

By implementing these control measures and following best practices, the impact of thermal spraying on air quality can be reduced, creating a safer and healthier working environment within the manufacturing facility.

Clean Air Solutions for Thermal Spraying

Central Collectors

Up to 40,500 CFM Airflow

Ruggedly designed for heavy-duty use, providing effective solutions for centralized fume and dust collection.

Learn More