Laser Cutting

What is Laser Cutting?

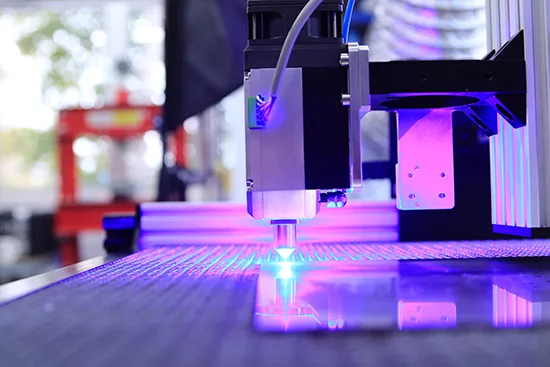

Laser cutting is a manufacturing process that utilizes a high-powered laser beam to cut or engrave materials such as metal, wood, plastic, or glass. The laser beam is focused on a small spot, generating intense heat that melts, burns, or vaporizes the material, creating a precise cut or engraving.

Laser cutting is a manufacturing process that utilizes a high-powered laser beam to cut or engrave materials such as metal, wood, plastic, or glass. The laser beam is focused on a small spot, generating intense heat that melts, burns, or vaporizes the material, creating a precise cut or engraving.

Laser cutting is widely used in various industries, including automotive, aerospace, electronics, and signage, among others. It offers several advantages over traditional cutting methods, such as increased precision, speed, and versatility. The process can create intricate designs, sharp edges, and complex shapes with minimal material waste.

Impact on Indoor Air Quality

Regarding the impacts on air quality within a manufacturing facility, laser cutting can introduce certain pollutants into the air. The composition of these pollutants depends on the material being cut and the specific laser cutting system used.

Here are some potential air quality impacts associated with laser cutting:

- Particulate Matter: When the laser interacts with the material, it can create airborne particulates, such as dust, fumes, or smoke. The size and composition of these particles vary based on the material being cut. For example, cutting metals can generate metal fumes, while cutting plastics can release toxic gases.

- Volatile Organic Compounds (VOCs): Some materials, particularly plastics, contain VOCs that can be released as gases during laser cutting. VOCs can contribute to poor indoor air quality and may have harmful effects on human health.

- Odors: Laser cutting certain materials, such as plastics or certain woods, can produce strong odors. These odors may be unpleasant and potentially irritating to individuals working in the facility.

What You Can Do

To mitigate the impacts on air quality, manufacturing facilities employ various control measures, such as:

- Ventilation Systems: Implementing effective ventilation systems, including local exhaust hoods and general ventilation, helps capture and remove contaminants at the source. This helps minimize their dispersion into the work environment.

- Air Filtration Systems: Air filtration systems, such as particulate filters and activated carbon filters, can be installed to remove particles and VOCs from the air, improving air quality.

- Material Selection: Choosing materials that generate fewer pollutants during laser cutting can help reduce the impact on air quality. Some materials have lower emission levels or are specifically designed for laser cutting processes.

- Work Practices: Adhering to safe work practices, such as proper maintenance of laser cutting equipment, regular cleaning, and appropriate handling and disposal of waste materials, can minimize air quality impacts.

By implementing these measures, manufacturers can mitigate the potential negative impacts on air quality associated with laser cutting and maintain a healthier work environment for their employees.

Clean Air Solutions for Laser Cutting

Central Collectors

Up to 40,500 CFM Airflow

Ruggedly designed for heavy-duty use, providing effective solutions for centralized fume and dust collection.

Learn More

Environmental Booths

Welding & Grinding

Durable and reliable, environmental booths are a self-contained, highly-customizable solution for welding, grinding, and more.

Learn More

Custom Extraction Hoods

Various Configurations

Customized extraction hoods built to your specifications. Can be suspended or mounted on legs.

Learn More