Benefits Of Weld Fume Extraction In The Workplace

Clean Air Industries

on

June 1, 2024

Many employees all across the world spend the majority of their days at work. Therefore, it is the responsibility of business owners to make sure that the working environment is conducive to being safe and comfortable for their employees. A safe workplace is crucial for every employee’s productivity, health, and increased staff effectiveness on the job.

Especially in high-risk industries like mining and manufacturing, workplace safety should be a top priority. These industries use the welding process quite frequently, exposing everyone in the zone to harmful fumes which can affect the respiratory system and adversely impact their health and safety.

Particulate matter of hazardous metals like aluminum and lead and gases like argon, nitrogen, hydrogen fluoride, and carbon monoxide can be detected in welding fumes. Long-term exposure to these fumes can cause a number of cancers, including lung, throat, and urinary tract cancer.

Employers are accountable for the workplace environment, safety precautions, and how machine operations are carried out. Observing the regulations set forth by OSHA, AWS, and NIOSH, you can guarantee the health and safety of your personnel.

Fume extraction systems are an excellent solution for such workplace issues, particularly in the manufacturing industry. If your work is more welding-oriented and involves the production of hazardous fumes, consider investing in a suitable welding fume extractor.

What Is A Welding Fume Extractor?

Weld fume extraction systems are tools utilized to remove welding fumes produced when working with metals used in welding applications. The use of a vacuum mechanism is to suck the fumes from the source of production such that the toxic fumes do not get an opportunity to escape into the welding room or other functioning areas.

This equipment is usually made for industrial purposes. Fixed suction systems are mainly designed and conceptualized by industry-leading companies in accordance with the needs of the customer to create a perfect plan for extracting the  welding fumes through the insertion of airflow pipes that will filter the air to purify and reuse in the same environment.

welding fumes through the insertion of airflow pipes that will filter the air to purify and reuse in the same environment.

Additionally, a number of different designs are available for the assembly of the mechanical arms that provide the suction depending on their length and the perimeter of the surface where the welding process will take place.

Applications Of Fume Extraction Systems

Every job that requires welding or the creation of small particles and toxic fumes can use a fume extraction system.

- Brazing and soldering

- Grinding and deburring

- Smelting

- Laser cutting

- Manual welding

- Plasma cutting

- Sanding

- Robotic welding

- Manufacturing

- Powder filling

Methods Of Weld Fume Extraction

An efficient fume extraction system will protect workers from health hazards by keeping dangerous fumes below the prescribed levels. Select a welding fume extraction system manufactured and designed to meet your work-specific requirements.

This diversity of requirements is why we have different fume extraction methods that can fit different needs. The five most prevalent techniques are as follows:

1. Portable welding fume extractor

Portable weld fume extractors have a filter fitted inside a frame with casters. It consists of a snorkel or an arm attached to a blower. It requires the snorkel to be placed at the center to be effective. Therefore, as the object being welded moves, the arm must be moved too. It also requires frequent filter changes.

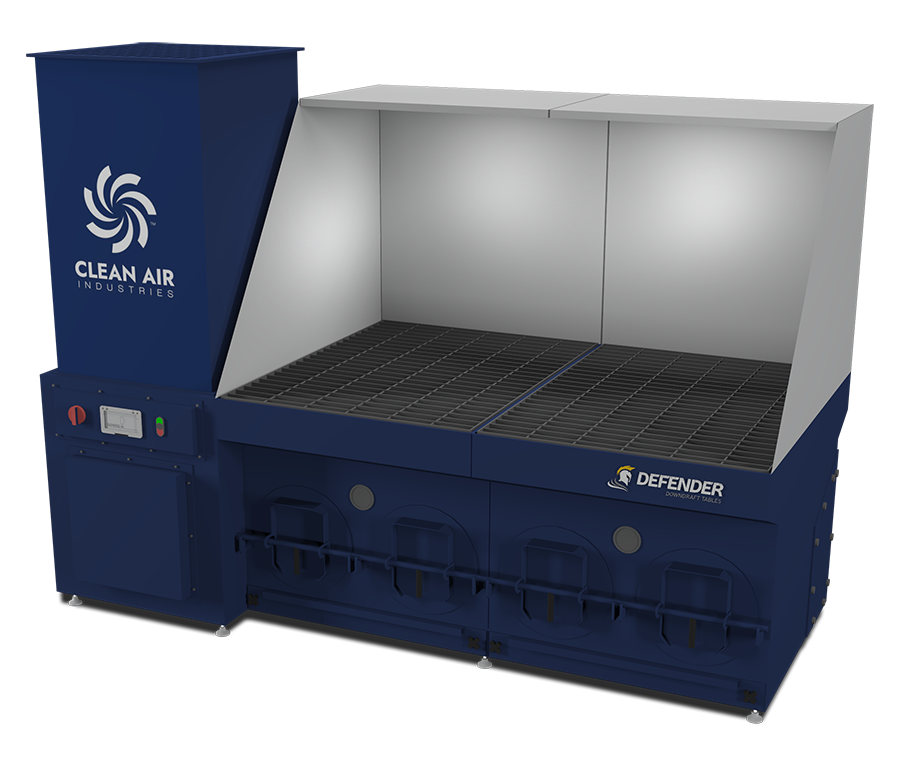

2. Self-contained downdraft tables

In a self-contained downdraft table, the filters are placed inside the table, and the blower pulls air from the environment. This technique has the minimum installation requirements and costs just as much as a portable welding fume extractor. Self-contained downdraft tables are the safest solution for welding and grinding purposes.

3. Empty downdraft tables

These rely on the operations of a central fume and dust collector to take the collected air away from the operator into an external collector. They are not ducted and do not need power. One major strength of this technique is that empty downdraft tables are highly customizable and flexible but bring on a lot of additional expenses in installation and scalability.

4. Central fume and dust collectors

Empty downdraft tables are ducted to central fume and dust collectors. They do not need much maintenance as filters will typically only require an annual change although this will vary depending on the type of metal being welded, and the presence of oil on the metal surface.

5. Hanging ambient air cleaners

Hanging ambient air cleaners work as a secondary cleaning system to remove the leftover residues of harmful fumes after the primary solutions. The units are typically installed 12-14 feet above the ground, either suspended from the ceiling or mounted on a wall. Generally, they are an affordable and quick solution.

Why Is Welding Fume Hazardous?

Welding processes first appear to be safe. Simply uses heat to join two or more metal components, right? But several risks are involved, many of which are directly connected to the air you breathe. Welding fumes are hazardous due to the welding particles they contain, which are the source of airborne contaminants, such as:

- Carbon Dioxide

- Ozone

- Sulfur Dioxide

- Nitrogen Oxides

- Lead

- Aluminum Oxides

If you are unsure how these chemicals affect you, let us list the problems for you. Long and short-term exposure to these chemicals is linked to a number of health issues, including:

- Throat Cancer

- Lung cancer

- Respiratory issues

- Nervous system damage

- Vision problems

- Acute Pneumonia

- Fume fever

Welding fumes contain carcinogenic chemicals in high amounts that might result in malignant tumors in the body. As understood from the discussion above, these compounds have a harmful effect on the human body, both mentally and physically. In general, a number of variables, including genetic predisposition or environmental effects and personal immunity, influence the risk of developing cancer. This is why we do not have an exact quantified count of the impact these substances can have. However, there is evidence that the risk of cancer rises with increasing exposure to these dangerous compounds in welding fumes.

Many studies have discovered that welders have a higher chance of developing lung cancer because of long hours of exposure.

What To Consider Before Choosing A Fume Extractor

To maintain exposure at or below an acceptable level, it’s crucial to consider the work conditions, practices, and risks in the welding applications in your facility before beginning to choose a welding fume extraction system.  Weld fumes extraction systems need to be placed correctly and used with necessary guidelines based on the specific requirements of the space in order to ensure effectiveness.

Weld fumes extraction systems need to be placed correctly and used with necessary guidelines based on the specific requirements of the space in order to ensure effectiveness.

When buying a welding fume extractor, you can ask yourself the following questions for a better idea of which type of fume extractor will work for your office.

- What is the size of your workshop or office where the welding process will happen?

- How much welding is likely to take place?

- What government-suggested regulations need to be met?

- Does the filter meet your application requirements?

- Is the fume extractor system flexible?

- Is the fume extractor system friendly for operators?

- Does the equipment meet the required level of airflow?

Benefits Of A Welding Fume Extractor

One of the best methods that guarantee safety in industrial environments through low exposure to hazardous fumes is to have fume extraction systems in the workplace. Employees can have efficient productivity in a safe working environment. Listed below are more such advantages linked to the operation of a fume extraction system in the workplace.

Improved Air Quality

Many offices in high-risk industries have poor air quality. It could harm your health if you or your employees spend most of the day in such a setting. However, you may enhance the quality of air and make your workplace healthier for everyone by using a weld fume extractor. The fume extractors function by collecting all of the fumes produced throughout the welding and manufacturing operations and releasing them into the air.

Improved Worker Productivity

Workers typically perform better when they are comfortable and in good health. Because a weld fume extractor minimizes welding fumes, you may give your staff a healthier working environment. Additionally, the team will take fewer days off, ultimately saving you money.

Improved Employee Morale

As they say, happy employees are productive employees. Your employees will immensely appreciate the safety precautions you take since they will see that you are concerned about their welfare. That can significantly improve everyone’s mental health and foster a positive work environment. This will be a step towards a better employer-employee relationship and building trust.

Reduced Absenteeism

A healthy workforce is directly related to a healthy workplace and lower absenteeism. As production increases, truancy will be lower, which is crucial for any organization. The majority of businesses are supposed to provide medical insurance for their staff members. If the workplace is unsafe and unsanitary, the expenses of treatment and medication for staff members as a result of the absence of a fume extraction filter could be quite high.

Healthier Work Environment

We all know that welding processes produce dangerous gases. Every welding procedure has some amount of fumes, and these gases can do a lot of harm if not handled carefully. Installing welding fume extractors in the welding area helps to ensure that all gases are quickly taken away from people before they can affect employees physically. The smaller the particles, the more dangerous they are. Fume extractors are essential to every welding sector for this reason.

Superior Weld Quality

The constant presence of fumes has an impact on the weld quality. The welds may become porous if the fumes are not sufficiently removed, resulting in weak and brittle joints. However, since a fume extractor will eliminate all dangerous vapors, you can enhance the weld quality.

Prevention of Corrosion

A number of corrosive gases are released in the office air during welding. These pollutants can also harm the surfaces and equipment in the office. Using a weld fume extractor in the workplace can be helpful in preventing metal pieces from corroding. Many industrial-grade fume extractors can assist in reducing corrosion.

Equipment Longevity

As mentioned above, the equipment used at work can also are impacted by the fumes created by welding. The equipment may be damaged and have a shorter lifespan due to the corrosive nature of welding fumes. Due to a fume extractor’s ability to eliminate corrosion, you can prolong the life of the machinery.

Conclusion

The benefits of fume extraction systems at a workplace are not restricted to workers only; they also benefit the company. In addition to reducing risks of illnesses, workers in a safe and healthy atmosphere will also be more attentive and energized. Additionally, workers have a tendency to be more self-assured in their surroundings at work, which benefits the people around them.

Employers must understand that even while a fume extraction system may appear to be unnecessary, the consequences of not having one will cost more. Therefore, it is only wise to install a fume extractor and watch your workers progress, as does your company.

Welding booths play a crucial role in schools by providing students with a safe and controlled environment to learn the art of welding. They not only develop students’ technical skills but also foster creativity, innovation, and problem-solving abilities. Welding booths create a hands-on learning experience that bridges the gap between classroom theory and real-world application, preparing students for successful careers in welding.

Welding booths play a crucial role in schools by providing students with a safe and controlled environment to learn the art of welding. They not only develop students’ technical skills but also foster creativity, innovation, and problem-solving abilities. Welding booths create a hands-on learning experience that bridges the gap between classroom theory and real-world application, preparing students for successful careers in welding.