In a world increasingly dominated by technology and digital learning, the importance of hands-on experiences cannot be overstated. And when it comes to vocational skills, welding is undoubtedly one of the most valuable and versatile. That’s where welding booths come into play. These specially designed spaces provide students with a safe and controlled environment to learn the art of welding, allowing them to ignite their creativity and passion for craftsmanship. But the benefits of welding booths extend far beyond the development of technical skills. By working in these dedicated spaces, students also cultivate a sense of discipline, attention to detail, and problem-solving abilities. In this article, we will explore why welding booths are crucial in schools, how they enhance the learning experience, and the long-term impact they have on students’ futures. So, let’s dive in and discover how creating a spark in the form of welding booths can ignite a lifelong love for hands-on learning.

Benefits of Hands-On Learning in Welding

Welding is a practical skill that requires hands-on experience to master. By providing students with the opportunity to engage in hands-on learning, welding booths offer numerous benefits. Firstly, hands-on learning allows students to apply theoretical knowledge in a practical setting, bridging the gap between classroom learning and real-world application. This experiential learning approach helps students develop a deeper understanding of the subject matter and enhances their critical thinking skills.

Secondly, hands-on learning in welding booths promotes creativity and innovation. When students have the freedom to experiment and explore their ideas, they become more confident in their abilities and are more likely to think outside the box. This fosters a spirit of innovation and problem-solving, essential skills for success in the ever-evolving world of welding.

Lastly, hands-on learning in welding booths instills a sense of pride and accomplishment in students. As they see their creations come to life, students gain a sense of ownership and a feeling of achievement. This boosts their self-esteem and motivates them to continue pursuing their passion for welding.

In summary, hands-on learning in welding booths is vital for students as it allows them to apply theoretical knowledge, promotes creativity and innovation, and fosters a sense of pride and accomplishment.

Importance of Welding Safety in Schools

When it comes to welding, safety should always be the top priority. In schools, where students are learning the fundamentals of welding, it is crucial to create a safe training environment that minimizes the risk of accidents. Welding booths play a vital role in ensuring the safety of students by providing a controlled space for them to practice their skills.

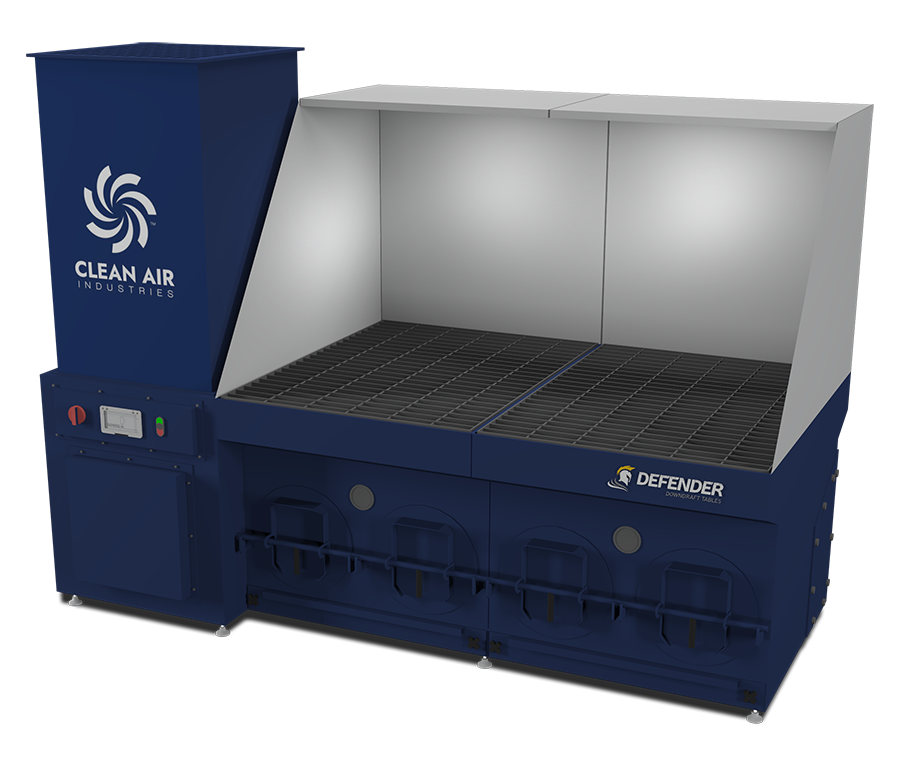

Welding booths are equipped with safety features such as ventilation systems, fire-resistant materials, and proper lighting. These features help prevent the accumulation of harmful fumes, reduce the risk of fire, and ensure optimal visibility during welding operations. Additionally, welding booths are designed to contain sparks and prevent them from spreading, further enhancing the safety of students and the surrounding environment.

By emphasizing the importance of welding safety in schools and providing dedicated welding booths, educational institutions demonstrate their commitment to the well-being of their students. This not only instills a culture of safety among students but also prepares them for a career in welding where safety practices are of utmost importance.

Types of Welding Booths and Their Features

Welding booths come in various types, each with its own unique features and benefits. The choice of welding booth depends on factors such as the size of the school, the number of students, and the specific welding techniques being taught. Let’s explore some common types of welding booths and their features:

1. Standard Welding Booths: Standard welding booths are the most basic type and are suitable for schools with limited space or a smaller number of students. They provide the necessary safety features such as ventilation, fire-resistant materials, and proper lighting. Standard booths are often modular, allowing for easy installation and customization.

2. Multi-Station Welding Booths: Multi-station welding booths are designed to accommodate multiple students simultaneously. These booths feature individual workstations equipped with welding equipment and safety measures. Multi-station booths promote collaboration and peer learning, allowing students to observe and learn from each other’s techniques.

3. Advanced Welding Booths: Advanced welding booths are ideal for schools that offer advanced welding techniques or specialized training. These booths may include additional features such as integrated exhaust systems, advanced safety controls, and computerized monitoring. Advanced booths provide students with a more immersive and technologically advanced learning experience.

4. Mobile Welding Booths: Mobile welding booths are designed for schools that require flexibility in their welding programs. These booths are portable and can be moved to different locations within the school or even taken off-site for field trips or community outreach programs. Mobile booths offer convenience and versatility without compromising on safety and functionality.

No matter the type of welding booth chosen, it is essential to ensure that it meets industry standards and regulations to guarantee the safety and well-being of students.

Setting up a Welding Booth in a School

Setting up a welding booth in a school requires careful planning and consideration. Here are some steps to follow when setting up a welding booth:

1. Assess the Space: Evaluate the available space in the school and identify an area suitable for the welding booth. Consider factors such as ventilation, access to electrical outlets, and proximity to other classrooms or workshops.

2. Ensure Proper Ventilation: Adequate ventilation is crucial in a welding booth to remove harmful fumes and ensure a safe working environment. Install a ventilation system that meets industry standards and regulations.

3. Choose the Right Welding Equipment: Select welding equipment that is suitable for the skill level and techniques being taught. Consider factors such as power requirements, durability, and ease of use.

4. Install Safety Measures: Implement safety features such as fire-resistant materials, proper lighting, and safety shields. Ensure that the booth is equipped with fire extinguishers and first aid kits.

5. Train Staff and Students: Provide comprehensive training to staff and students on the safe use of the welding booth and equipment. Emphasize the importance of following safety protocols and provide ongoing supervision and support.

By following these steps, schools can create a safe and functional welding booth that enhances the learning experience for students.

Best Practices for Using Welding Booths in Schools

To maximize the benefits of welding booths in schools, it is essential to implement best practices for their use. Here are some recommendations:

1. Safety First: Prioritize safety at all times. Ensure that students and staff are aware of and follow safety protocols, including the use of personal protective equipment (PPE) such as welding helmets, gloves, and safety glasses.

2. Supervision and Support: Provide adequate supervision and support to students during welding activities. Assign qualified instructors or supervisors who can guide students, answer questions, and address any safety concerns.

3. Regular Maintenance: Conduct regular maintenance checks to ensure that the welding booth and equipment are in good working condition. Inspect ventilation systems, electrical connections, and safety features to identify and address any issues promptly.

4. Encourage Collaboration: Foster a collaborative learning environment by incorporating group projects or team-based activities in the welding curriculum. Encourage students to share their knowledge and skills with their peers, promoting a sense of camaraderie and teamwork.

5. Document Learning Outcomes: Keep track of students’ progress and learning outcomes through regular assessments and documentation. This allows educators to identify areas of improvement and tailor the curriculum to meet the specific needs of each student.

By implementing these best practices, schools can ensure that welding booths are utilized effectively, resulting in a more enriching and rewarding learning experience for students.

Incorporating Welding Booths into the Curriculum

Integrating welding booths into the curriculum is crucial for providing students with a comprehensive learning experience. Here are some ways to incorporate welding booths into the curriculum:

1. Structured Lesson Plans: Develop structured lesson plans that align with the learning objectives of the welding program. Break down the curriculum into modules or units and design activities that allow students to practice their skills in the welding booth.

2. Real-World Applications: Include real-world applications of welding techniques in the curriculum. For example, students can work on projects that simulate industry scenarios, such as building structural components or fabricating artistic sculptures.

3. Guest Speakers and Industry Visits: Invite guest speakers from the welding industry or organize visits to local welding shops or manufacturing facilities. This exposes students to real-life welding practices and provides them with insights into potential career paths.

4. Certification Programs: Offer certification programs in collaboration with industry partners or professional welding organizations. These programs provide students with recognized credentials, enhancing their employability and opening doors to further career opportunities.

By integrating welding booths into the curriculum, schools can ensure that students receive a well-rounded education that prepares them for a successful career in welding.

Training and Certifications for Welding in Schools

To ensure the quality and relevance of welding education in schools, it is essential to provide training and certifications for both students and instructors. Here are some training and certification options:

1. Student Certifications: Offer certification programs specifically designed for students. These certifications validate their skills and knowledge in specific welding techniques and can be a valuable addition to their resumes.

2. Instructor Certifications: Provide opportunities for instructors to obtain certifications in teaching welding. These certifications ensure that instructors have the necessary expertise to deliver high-quality instruction and maintain industry standards.

3. Continuing Education: Encourage both students and instructors to engage in continuing education programs to stay updated with the latest advancements in welding technology and techniques. This can be achieved through workshops, seminars, or online courses.

4. Collaboration with Industry Partners: Partner with local welding businesses or organizations to offer apprenticeship programs or internships. These programs provide students with hands-on experience and exposure to real-world welding practices.

By investing in training and certifications, schools demonstrate their commitment to providing students with a comprehensive and industry-relevant education in welding.

Funding Options for Purchasing Welding Booths

Acquiring welding booths for schools can be a significant investment. Fortunately, there are several funding options available to support the purchase of welding booths. Here are some potential funding sources:

1. Government Grants: Explore government grants and funding programs specifically designed for vocational education or career and technical education. These grants often prioritize the acquisition of equipment, such as welding booths, that enhance hands-on learning experiences.

2. Private Donations: Seek support from local businesses, corporations, or philanthropic organizations that have an interest in promoting vocational education. Many companies have corporate social responsibility programs or foundations that provide grants or donations to educational institutions.

3. Partnerships with Industry: Establish partnerships with local welding businesses or industry associations. These partnerships can provide financial support, equipment donations, or access to discounted prices for welding booths.

4. Fundraising Events: Organize fundraising events within the school or the local community to generate funds for purchasing welding booths. These events can include auctions, raffles, or sponsorships.

It is essential to research and explore multiple funding options to find the most suitable and sustainable solution for acquiring welding booths for schools.

Conclusion: The Impact of Welding Booths on Student Learning

Welding booths play a crucial role in schools by providing students with a safe and controlled environment to learn the art of welding. They not only develop students’ technical skills but also foster creativity, innovation, and problem-solving abilities. Welding booths create a hands-on learning experience that bridges the gap between classroom theory and real-world application, preparing students for successful careers in welding.

Welding booths play a crucial role in schools by providing students with a safe and controlled environment to learn the art of welding. They not only develop students’ technical skills but also foster creativity, innovation, and problem-solving abilities. Welding booths create a hands-on learning experience that bridges the gap between classroom theory and real-world application, preparing students for successful careers in welding.

By emphasizing the importance of welding safety and implementing best practices for using welding booths, schools can ensure that students receive a comprehensive and safe learning experience. Integrating welding booths into the curriculum, providing training and certifications, and exploring funding options further enhance the impact of welding booths on student learning.

In a world where technology continues to advance, the need for hands-on experiences in vocational skills like welding becomes even more critical. Welding booths create a spark of passion and ignite a lifelong love for hands-on learning, empowering students to pursue fulfilling careers in welding and related fields. So, let’s continue to create sparks and build a future where hands-on learning thrives in schools.

Literature

Welding booths play a crucial role in schools by providing students with a safe and controlled environment to learn the art of welding. They not only develop students’ technical skills but also foster creativity, innovation, and problem-solving abilities. Welding booths create a hands-on learning experience that bridges the gap between classroom theory and real-world application, preparing students for successful careers in welding.

Welding booths play a crucial role in schools by providing students with a safe and controlled environment to learn the art of welding. They not only develop students’ technical skills but also foster creativity, innovation, and problem-solving abilities. Welding booths create a hands-on learning experience that bridges the gap between classroom theory and real-world application, preparing students for successful careers in welding.